What Maximum Distance Should A Restraint Strap Be Fixed

Importance of Secure Restraint Strap Fixing

Restraint straps play a critical role in maintaining the structural integrity of buildings, particularly for lateral and vertical stability. They provide resistance against wind uplift and other force stresses.

Used in conjunction with components like Timber Frame Connectors, restraint straps ensure that joints between structural elements remain firmly connected. Proper installation and correct spacing are essential to guarantee full load transfer and sustainability over time.

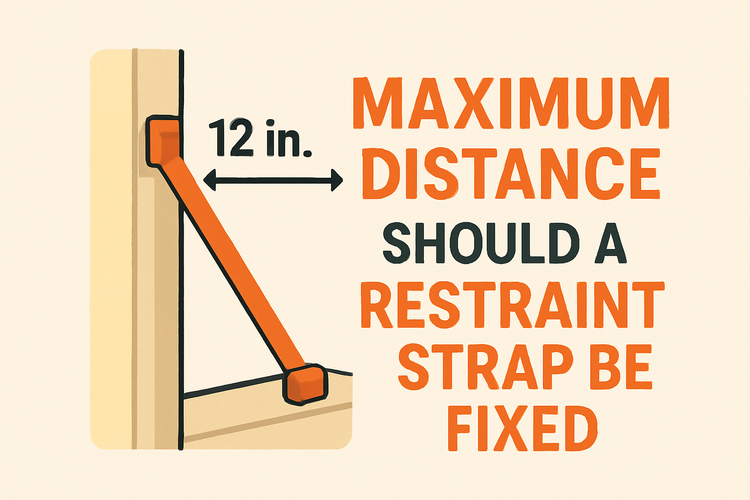

Recommended Maximum Distance for Fixing Restraint Straps

In general construction standards, the maximum fixing distance for restraint straps shouldn’t exceed 2 meters. This ensures effective load transfer and avoids compromising structural performance.

Support should be provided at no greater than 2m centers for horizontal restraint straps and vertical wall straps, particularly in cavity walls or timber frame applications. The manufacturer guidelines often stipulate these constraints, and it's crucial they are followed.

Overextending the distance can lead to buckling under pressure or ineffective bracing during adverse conditions such as high winds or load-bearing scenarios. Products like High Wind Ties & Timber Connectors are often used in tandem to bolster structural reliability under extreme conditions.

Always ensure that the fixing is continuous along the specified run to maximize the performance benefits of the straps and to distribute forces evenly across the structure.

Material and Fixing Type Considerations

The material of both the wall and the strap itself strongly influences how securely and what distance the restraint strap can be fixed. Galvanised steel straps, for example, are commonly used due to their high strength and corrosion resistance.

Timber, masonry, and steel frame environments each require specialized fixings, often with supplemental supports like Angle Brackets or Post Bases, to ensure fitting integrity. The use of the correct type of anchor or screw is just as important as the strap distance itself.

For masonry walls, it’s essential to anchor straps into the structural units rather than just the surface plaster or render. Resin anchors or expansion bolts often serve this purpose for added security. On timber structures, straps are typically nailed or screwed into solid joists or wall plates for maximum grip.

When choosing fixings, always account for environmental factors like moisture or external exposure, as they can affect long-term hold strength of both strap and anchor point.

Installation Practice and Spacing Standards

Correct installation is crucial to ensure the restraint straps function as designed. Apart from distance, the alignment, fixing method, and type of surface all contribute to overall efficiency.

Nailing or screwing into every predetermined hole on the strap is necessary to harness its full restraint capability. Skipping fixing points or inconsistent anchoring could compromise the structural resistance to uplift or lateral movement. Keeping the strap entirely flat and tensioned during installation is also recommended to avoid future disturbances.

BS 5268 and Eurocode standards advise that vertical straps should be spaced no more than 1.8 metres apart, particularly where floors and roof structures meet walls. Meanwhile, horizontal straps, such as those tying walls back to floors or roofs, demand not more than 2 metres in spacing intervals. These regulations help reduce the risk of structural movement or cracking, especially in taller or more exposed buildings.

Structural Integration with Other Components

Restraint straps don’t operate in isolation—they are part of a broader reinforcement system. Effective structural connections come from integrating multiple components designed to support each other under various load conditions.

For example, within timber frames, restraint straps seamlessly complement fixings like Joist Hangers to maintain alignments and transfer stresses appropriately. Similarly, in roof structures, they pair with Roof Connectors to provide additional rafter or truss security.

When working with modern engineered timber elements like cross-laminated timber (CLT) or glulam, restraint straps are often used in combination with dedicated connectors. This synergy ensures that all joints are secured against movement while allowing the natural flexibility or expansion of wood across seasons.

Combining restraint straps with strategic connector placement dramatically enhances the structure’s ability to withstand both static and dynamic forces, resulting in smarter, long-lasting construction methodologies.