What Is A Joist Hanger

Understanding What a Joist Hanger Is

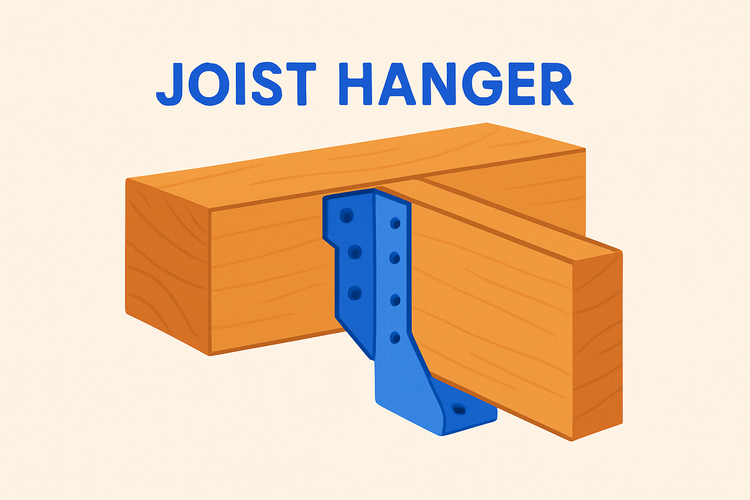

A joist hanger is a metal bracket designed to support the connection of a joist to a beam or ledger board. It plays a critical role in providing stability and strength to floor or ceiling framing systems.

Joist hangers are a key component in both residential and commercial construction, helping distribute loads evenly and prevent structural failures. They come in a variety of sizes and configurations to match different lumber dimensions and load requirements. Made typically of galvanized steel, they resist corrosion and can endure significant stress, ensuring secure structural framing over time.

Types of Joist Hangers for Different Applications

There are several types of joist hangers tailored for specific structural purposes. Choosing the correct type depends on the orientation, weight, and environmental conditions of the structure.

The most common types of joist hangers include face mount, top mount, skewed, and sloped hangers. Face mount hangers attach to the face of a supporting beam, while top mount hangers sit on top and are typically used in concealed framing applications. Skewed or angled hangers are useful in applications where joists come in at an angle, such as in hip roofs or irregular framing layouts.

In coastal or outdoor environments, stainless steel or hot-dipped galvanized joist hangers are recommended due to their resistance to corrosion. Some applications may also require heavy-duty hangers, which are reinforced to support greater loads or provide additional stability for longer spans. These specialized hangers must meet certain building codes and load-bearing specifications for safety.

How Joist Hangers Are Installed Properly

Installing joist hangers correctly ensures structural integrity and long-term durability. Careful attention to detail during installation is crucial.

The first step in installation is positioning the joist hanger in the appropriate location on the ledger board or beam. It must be flush and level to distribute weight evenly. Fastening is done using manufacturer-recommended nails or screws—typically galvanized for durability. Do not substitute with non-approved fasteners, as this can compromise strength.

Once the hanger is secured, the joist is inserted into the saddle or pocket. Additional fasteners secure the joist within the hanger, locking it firmly in place. It's important that all predrilled nail holes in the hanger are used to ensure the design load is fully supported. Inspectors often check this detail during framing inspections.

When working on large framing projects, using a template or jig can speed up hanger placement and increase precision. Joist hangers that are improperly aligned or under-secured can shift over time under weight, leading to deflection and eventual structural issues.

Benefits of Using Joist Hangers in Construction

Joist hangers offer several critical benefits to builders, engineers, and property owners alike. These benefits make them a preferred method for ensuring strong, uniform framing connections.

One of the primary advantages is their ability to provide consistent load transfer between joists and supporting beams. Unlike traditional notching or toe-nailing methods, joist hangers eliminate guesswork and improve the overall strength of a structure. They also help prevent joist twisting or warping, which can occur over time due to stress or moisture exposure.

The use of joist hangers also allows builders to complete framing jobs more efficiently. Their versatile designs make it easier to work within tight spaces or accommodate unusual framing orientations. In addition, modern hangers come with features like guide tabs and one-piece construction, reducing installation time and increasing safety.

For code compliance, most modern building regulations require or recommend hangers in specific framing situations, particularly wherever joists connect to girders or ledger boards. Using approved hangers simplifies the inspection process, reduces liability, and demonstrates a commitment to professional building standards.

Common Mistakes to Avoid With Joist Hangers

Even though joist hangers are straightforward to use, there are common mistakes that can compromise their performance and safety. Avoiding these errors is crucial to ensuring a stable structure.

One frequent mistake is selecting the wrong type or size of hanger for the load or joist material. Joists must fit snugly within the hanger pocket, with no more than 1/8 inch of gap. Using undersized hangers can lead to sagging or even failure over time. It’s also essential to match hangers with appropriate fasteners; using incorrectly rated nails or screws can significantly reduce the hanger’s capacity.

Another issue is improper alignment during installation. If joist hangers are not level or centered, it can cause uneven weight distribution and accelerated wear. Builders should use levels, jig guides, or markings to double-check positioning before securing hangers.

Lastly, ignoring building code requirements or failing to install all fasteners as specified can result in code violations and unsafe conditions. Adhering strictly to manufacturer guidelines and consulting with structural engineers when needed ensures long-term structural integrity and safety for the occupants of the space.