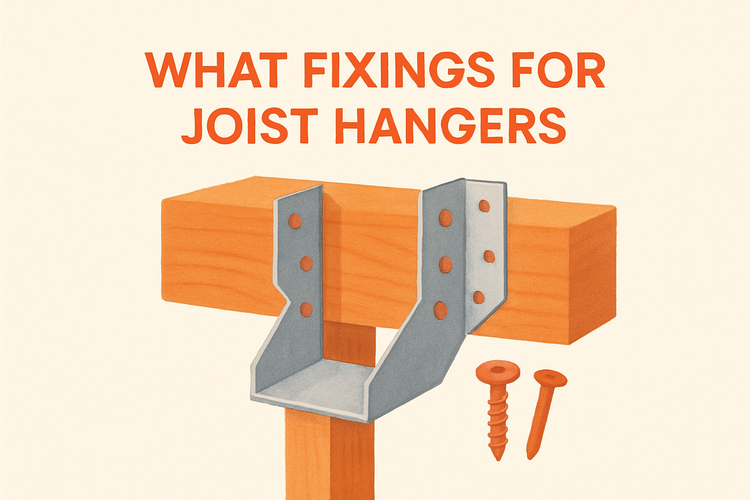

What Fixings For Joist Hangers

Choosing the Right Fixings for Joist Hangers

Joist hangers are only as strong as the fixings used to install them. Using the wrong fasteners can severely compromise structural integrity, regardless of how durable the hanger may be.

In general, the most reliable fixings are nails or screws specifically rated for structural use. Galvanised or stainless steel options help ensure long-lasting strength while resisting corrosion. It's crucial to follow manufacturer specifications to ensure the fixing type and length match your specific joist hanger configuration. These fasteners need to penetrate deeply into supporting timber or masonry for maximum holding power. For an extensive selection of screws and nails ideal for joist hangers, browse the available options tailored for timber connections.

Galvanised Screws vs Nails for Load-Bearing Applications

Nails are traditionally used with joist hangers due to their capacity to flex under axial loads. However, modern structural screws have emerged as a strong alternative, offering high pull-out resistance and easier installation without the need for impact tools.

The primary concern when choosing between nails and screws is shear strength versus withdrawal resistance. Nails offer better shear strength, which is often required in horizontal load applications. Galvanised nails, particularly annular ring shank nails, provide excellent holding power and are corrosion-resistant – essential for outdoor or humid environments. On the other hand, screws are best for precision placement and add strength in vertical applications.

Some joist hangers are tested and rated only with specific nails or screws. It's essential to refer to the documentation that comes with the hanger, as deviations in fastener choice can void warranties or compromise safety. In newer construction practices, approved structural screws are becoming a preferred alternative due to their speed and comparable strength values.

Fixing Length and Diameter: What Matters Most

Fastener length and diameter play a crucial role in a joist hanger’s load capacity. Undersized fixings can fail under pressure, while oversized fixings may damage the hanger or surrounding materials.

Typically, 3.75mm x 30-50mm galvanised nails are used for light-duty hangers, while higher capacity applications may require longer or thicker variants. Structural screws usually range between 45mm to 75mm depending on timber depth and hanger gauge. Matching the fastener diameter with hanger's pre-drilled holes ensures proper load distribution and prevents splitting in timber joints.

In particular, long fixings deliver enhanced withdrawal resistance – critical where vertical loads dominate. It’s also vital to ensure that the fixing penetrates both structural components with sufficient embedment to adequately carry intended loads. For larger joinery systems like post base supports, heavier duty fixings with industrial torque ratings are recommended.

When to Use Stainless Steel Fixings

In corrosive environments, stainless steel fixings are a must. Areas exposed to salt, moisture, or chemicals will quickly deteriorate galvanised materials if not properly protected.

Outdoor decking, coastal construction, and public infrastructure projects all benefit from stainless steel's superior corrosion resistance. Though more costly, stainless steel fixings prevent structural failures caused by rusting nails or screws. They are particularly necessary when fixings are in contact with treated lumber, which contains chemicals known to accelerate corrosion in ordinary galvanised metals.

Joist hangers designed for outdoor environments often specify 316-grade stainless steel screws or nails. This grade offers the highest protection and is a long-term investment in safety and durability. Be sure to use fixings compatible with metal hangers to avoid galvanic corrosion, a reaction that can occur when dissimilar metals contact each other in moist conditions.

Installation Tips to Maximise Strength

Proper installation technique is just as important as using the right type of fixing. Avoid shortcuts, and make sure all holes in the joist hanger are filled unless specified otherwise by the manufacturer.

Start by aligning the hanger accurately on the beam or ledger board. Use a clamp to hold the hanger in place during initial fixing, ensuring no movement occurs. Always drive fixings perpendicular to the surface for optimal grip. Do not reuse bent nails or overdrive screws, which can damage the wood or deform the hanger shape, reducing effectiveness.

Power tools like impact drivers should be set to avoid overdriving screws, which can break through timber fibres. For longer fixings, pre-drilling may be required to prevent splitting. Refer to manufacturer guidelines for exact spacing and fixing patterns. Visit our joist hanger collection for all compatible hardware, specifications, and installation accessories.