How To Use Timber Frame Connectors

Understanding the Role of Timber Frame Connectors

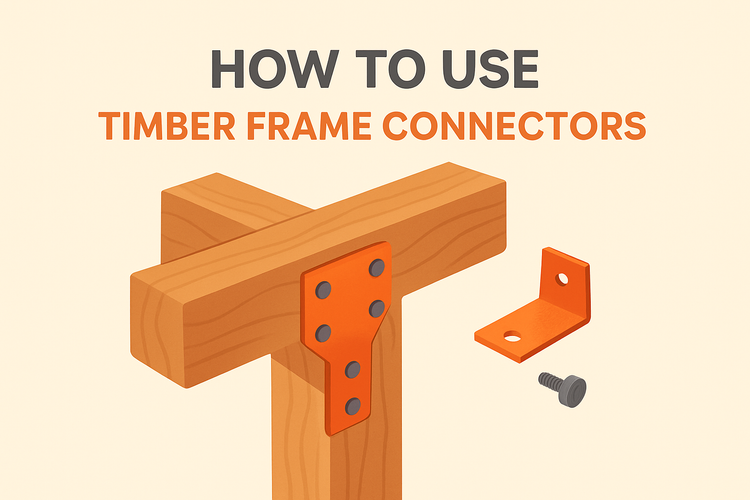

Timber frame connectors are essential in modern construction, providing structural support and improving the load-bearing capacity of wooden frameworks. They enable strong, stable junctions between timber elements, crucial in both residential and commercial buildings.

Available in various designs, timber frame connectors accommodate multiple joint angles and load conditions. Using the appropriate connector ensures integrity in high-stress areas, such as roof joints and wall corners. These connectors contribute significantly to the overall longevity and safety of timber-framed structures by resisting forces like tension, compression, and shear.

Beyond structural performance, timber frame connectors promote efficient assembly, supporting both off-site fabrication and on-site installations. They enhance construction speed, reduce labour effort, and ensure systematic alignment, which reduces the need for adjustments. For builders and contractors seeking higher strength and simplified processes, connectors are indispensable.

Choosing the Right Connector for Your Application

Selecting the appropriate timber frame connector depends largely on the type of joint you’re reinforcing and the forces likely to be experienced in that part of the structure. Proper selection leads to a durable and sound assembly.

For example, angle brackets offer excellent performance in reinforcing 90° joints, ideal for wall and post-frame connections. Products like angle brackets come in different shapes and sizes tailored for specific applications, including concealed installations and decorative joinery. Understanding load types—whether lateral, axial, or uplift—also dictates which connector is most effective.

Other applications benefit from more specialised solutions. High-load areas may require high wind ties and timber connectors, designed to resist shear forces caused by wind or seismic activity. The right connector ensures safety, compliance with standards, and long-term stability.

Installation Tips for Timber Frame Connectors

Getting the installation right is just as important as choosing the correct connector. Poor installation can compromise structural strength and negate the benefits of timber connectors.

Before fastening, always ensure timber surfaces are flush, level, and free from splits or damage. Use approved fasteners like those found in the screws and nails section to meet load ratings. Incorrect or mismatched fasteners can weaken even the most robust connector.

Where possible, pre-drilling holes can prevent wood splitting and improve screw alignment. Always consult the manufacturer’s specifications for torque settings and spacing. Tools like impact drivers, cordless drills, and clamps can streamline the process and ensure secure fittings. Post-installation inspections are also encouraged to check tensions and fastener engagement.

Integrating Post Bases in a Timber Frame System

Post bases are commonly used where vertical posts meet concrete foundations or floors. These connectors provide uplift resistance and protect timber from moisture exposure at ground level.

Modern post bases are designed to elevate wood slightly off the concrete surface, ensuring airflow and minimising moisture retention, which can lead to decay. They're often hot-dip galvanised for corrosion resistance and longevity. Installing these bases securely with anchor bolts into the foundation ensures lateral stability and a solid structural connection.

In taller frames, using post bases can help resist swaying and lateral movement. Some models come with adjustable brackets, ideal for sites with minor grade irregularities or retrofitting onto existing slabs. Selecting a base that aligns with load-bearing requirements is essential in large span or load-heavy projects.

Maintaining Timber Frame Integrity with Regular Checks

Timber connectors play a long-term role in building performance, making it vital to perform regular inspections. Over time, timber contracts and expands, and metal fittings may loosen or corrode.

Watch for signs like surface rust, fastener movement, or timber splits near the joint. Early identification of wear allows you to replace or reinforce failing parts without extensive damage. This is particularly important in locations with high humidity or outdoor exposure. Components exposed to the elements should always be check against the manufacturer’s recommended maintenance schedules.

In addition to visual inspections, periodically verify that structural loads haven’t changed—renovations, added roofing materials, or new walls can shift the pressure on joint points. Strengthening affected areas with compatible timber frame connectors can renew stability and extend structural life.