How To Use Deck Joist Hangers

Understanding the Purpose of Joist Hangers

Joist hangers serve a crucial role in maintaining structural integrity when building decks. They are metal brackets used to anchor the ends of joists to a beam or ledger board, helping to distribute weight and ensure stability.

By using joist hangers, builders eliminate the need to notch or rest joists directly on the supporting frame. This reduces the chance of weakening the timber and enhances load-bearing capabilities. In harsh environments or outdoor builds like decks, these connectors help combat movement from moisture, temperature fluctuation, and shifting foundations.

Joist hangers are available in various configurations to suit different construction needs, including face-mount and top-mount options. The correct type will depend on your deck’s design and the direction the load is applied. Always select hangers that match the size of the joists you're using to ensure proper alignment and support.

Choosing the Right Joist Hanger for Your Deck

Selecting the correct joist hanger is the first step in ensuring the safety and longevity of your deck structure. Compatibility with the joist size and type of timber is critical.

The size of the joist hanger must match the dimensions of the joists exactly. For instance, if you're using 2x6 joists, then your joist hangers must be designed to fit a 2x6 timber. Many builders overlook this and attempt to compensate with extra nails or screws, a practice that can compromise the integrity of the build. Certain joist hangers are also treated to resist corrosion and are ideal for outdoor projects where moisture is prevalent.

Besides size, material plays an important role. Galvanised steel joist hangers are a durable and popular choice for deck construction. In regions with high humidity or near saltwater, special corrosion-resistant coatings are recommended. It's also worth considering additional hardware, like screws and nails designed specifically for use with joist hangers, to maintain compliance with building codes and avoid rust-related failures over time.

Always verify load ratings provided by the manufacturer and ensure they match or exceed the requirements of your project. Poorly chosen connectors can lead to sagging joists, deck instability, or even failure under heavy loads.

Installing Joist Hangers: Materials and Tools Needed

Before you begin installing joist hangers, make sure you have all necessary tools and materials on hand. Preparation is key for a smooth, safe installation.

You'll need a hammer or nail gun, appropriate fasteners (always choose those approved for structural connections), a measuring tape, a carpenter's square, and of course, the joist hangers themselves. If you're working on treated timber or exposed conditions, opt for hot-dipped galvanized or stainless steel fasteners to prevent rust. Using fasteners that match the corrosion resistance of the hanger is essential to ensure long-term durability.

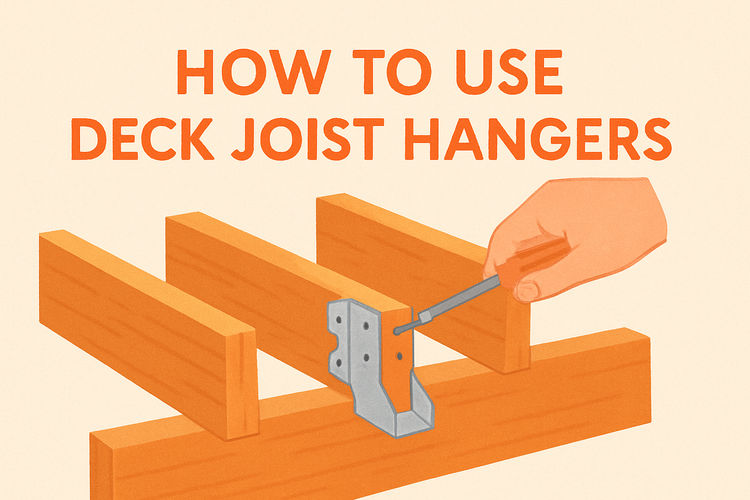

Joist hangers must be securely attached to the ledger board or beam before inserting the joist. Measure and mark the position before you begin nailing. Using a square ensures that the hangers are aligned perpendicular to the surface, which is crucial for proper support. Secure one side of the hanger first, then insert the joist and adjust if needed before fastening the opposite side. Slanted or poorly seated hangers lead to uneven decks and long-term issues with weight distribution and wear.

In some cases, you may also need supplementary connectors like high wind ties and timber connectors if building in storm-prone areas, adding another layer of resilience against lateral forces.

Common Mistakes to Avoid During Installation

Installing joist hangers may seem straightforward, but common errors can compromise structural integrity. Recognising and avoiding these mistakes is vital.

One of the most frequent issues is using incorrect fasteners. Screws or nails not approved for use with hangers will reduce the weight capacity, potentially leading to failure over time. Builders often substitute drywall screws or whatever nails are on hand instead of using required structural fasteners. Each hanger is designed to function with specific types and numbers of nails or structural screws, as overfastening or underfastening can reduce performance.

Misalignment is another issue. When joist hangers are installed crooked or off-center, they place uneven stress on the timber and fasteners. This can lead to premature wear or sagging joists. It's critical to measure and mark accurately with a square and level before attaching any hardware. Also, failing to seat the joist fully in the hanger before nailing reduces the effectiveness of the connection.

Lastly, not considering environmental conditions can be costly. For example, using basic steel hangers in damp, seaside environments will quickly lead to corrosion and joint failure. Opting for treated or stainless steel versions may cost more initially but offer much greater longevity and peace of mind.

Enhancing Structural Integrity with Additional Connectors

Joist hangers are just one component in achieving a solid, safe deck. Complementing them with other structural connectors can significantly boost performance and durability.

For decks exposed to high winds or located in earthquake-prone zones, using high wind ties and timber connectors provides extra lateral support. These ties help keep the entire frame together during lateral shifts or tremors, reducing the risk of movement that can destabilise a deck. Post base connectors are also essential, anchoring the vertical posts to the foundation and preventing uplift in storm conditions.

In more complex deck configurations, especially those with additional walls or overhangs, integrating restraint straps into the build helps keep opposing structural members connected. This long-span reinforcement ensures that flexing or expansion doesn’t lead to joint separation over time. Similarly, angle brackets and other framing connectors can support deck stairs, railings, and overhead covers, offering multi-directional stability where joist hangers alone would be insufficient.

For premium wood types or long-span engineered timbers like Glulam, explore options in connectors for Glulam timber to ensure full structural compliance and compatibility. Integrating these elements into your joist hanger-based deck means superior performance and longer-lasting results.