How To Tie Bricks To Wall

Understanding the Importance of Tying Bricks to a Wall

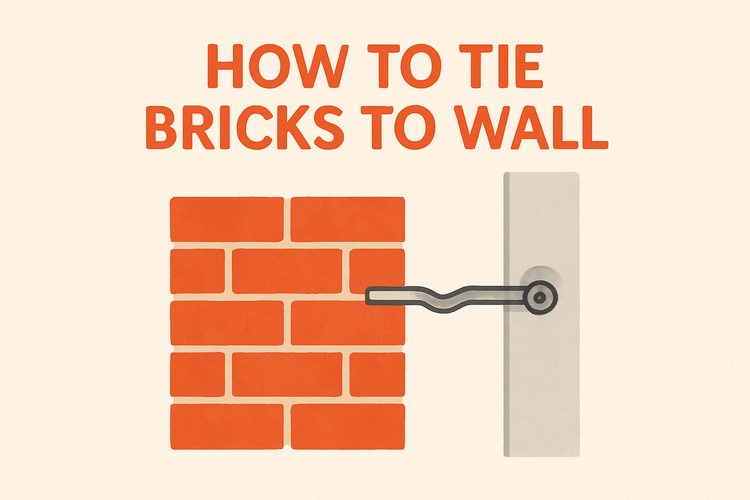

When constructing brick walls, it's crucial to secure them adequately to the structure to prevent lateral movement and ensure long-term stability. Tying bricks to a supporting structure isn’t just about safety—it’s also about maintaining the integrity of the build.

Structural connections between bricks and adjacent supports help distribute loads evenly and resist external forces like wind and gravity. By using proper connectors, such as masonry connectors and wall ties, builders can guarantee durability and compliance with safety standards.

Selecting the Right Wall Ties and Connectors

Choosing the correct wall ties is foundational to ensuring that bricks stay firmly attached to supporting structures. Different types of wall ties are available for varying brick wall constructions, from cavity walls to solid masonry.

For example, stainless steel wall ties are ideal for high-moisture environments due to their corrosion resistance, while heavy-duty wall ties are used in areas affected by high wind loads. Load-tested and certified wall ties and masonry connectors can be selected based on project-specific criteria such as wall thickness, material compatibility, and structural requirements.

It's also essential to consider the building's exposure to the elements. In zones with high rainfall or significant temperature fluctuations, thermal movement and moisture retention can affect the bond between bricks and mortar. Proper ties mitigate such issues by allowing for some flexibility while maintaining overall integrity.

Lastly, always consult building regulations and standards. What's adequate for a domestic build may not suit a commercial or multi-story structure. High-quality connectors from trusted suppliers ensure consistency across processes and peace of mind for builders and clients alike.

Using Wall Starter Profiles for New Wall Integration

Wall starter profiles are essential when building new walls adjacent to existing structures. They provide a stable anchorage point and help seamlessly integrate new brickwork with old.

These profiles are typically made of galvanized or stainless steel and are embedded directly into masonry or fixed using anchors and screws. This allows the new wall to move slightly due to thermal expansion or settling, without compromising structural safety. Starter profiles are particularly valuable in extensions, conservatory installations, and structural renovations.

When selecting a profile system, it’s vital to ensure you're choosing one compatible with your existing wall material. Brick-to-brick attachments differ from timber-to-brick setups, so using the proper wall starter profiles guarantees stability and adherence to code.

Installers should also pay attention to alignment and leveling during attachment. Even minor deviations in position can result in misaligned courses, creating an unsightly finished product. Following manufacturer guidelines ensures a neat, reliable connection every time.

Enhancing Stability with Angle Brackets and Restraint Straps

For additional support, items like angle brackets and restraint straps can reinforce the connection between bricks and structural components.

Angle brackets offer rigid, right-angle support especially where perpendicular walls join or where ledges and shelf structures intersect with masonry. These metal fixtures are easily installed during the building process and offer long-term stability. Pairing them with the correct fixing systems increases their effectiveness and reduces future maintenance issues.

Meanwhile, restraint straps provide strong ties at floor and ceiling connections, preventing lateral load movement. This is particularly important in areas where wind stresses or structural load shifts occur. Proper placement and anchoring into brickwork and joists ensure their success in reinforcing load-bearing structures.

In high wind zones, combining these components with high wind ties strengthens vulnerable sections significantly. For best performance, straps should be recessed or carefully aligned with joints to avoid creating pressure spots within the masonry.

Fixing Methods and Tools for Proper Attachment

Even the right connectors require correct installation practices. Using the appropriate screws, nails, and tools ensures that brick ties and brackets are securely and safely mounted.

Screws and nails designed for masonry and structural applications differ greatly from general-purpose fasteners. Selecting corrosion-resistant and load-rated options prevents loosening and degradation over time. Builders may choose between mechanical anchors, chemical fixings, and direct fasteners depending on the load expected and wall material.

Drilling into masonry requires careful technique to avoid cracks or breakages. Using a hammer drill, correct bit size, and measured depth reduces the chance of compromising the structural core while fixing ties or straps.

Labelling your materials and pre-planning fix points make the process smoother. Following an installation layout based on structural drawings helps maintain precision and minimizes post-installation shifting or rework.

Tying in Special Timber Components to Brickwork

When joining timber elements—like beams or floor joists—to brick walls, specialist connectors ensure secure integration and load distribution.

Joist hangers are often used where timber joists intersect with masonry walls. These brackets cradle the timber and fix directly into the brickwork, transferring loads effectively. Choosing hangers with a wide bearing surface increases strength and prevents timber deformation over time.

Similarly, post base connectors facilitate sturdy column-to-wall attachments. Placing timber posts on post base hardware ensures that posts are lifted from the ground, preventing degradation from moisture while anchoring them to the wall. These are key in both indoor structural frames and outdoor pergolas or timber fencing joined to brick.

Some advanced builds may integrate engineered timber such as glulam or cross-laminated timber (CLT). When tying CLT or glulam to masonry, using purpose-made connectors for cross laminated timber or connectors for glulam timber is advised, as they offer precision fit and enhanced structural performance. These are especially common in modern timber-framed homes or commercial hybrid builds where load transfer is critical.