How To Tie A Block Wall To An Existing Wall

Assessing the Existing Wall Structure

Before tying a new block wall to an existing structure, evaluate the condition and material of the existing wall. This ensures compatibility and stability of the new connection.

Assess the load-bearing capability, surface flatness, and type of construction in the existing wall—brick, concrete, or block. Older structures may require reinforcement to accommodate the new block wall. Cracks or water damage should be addressed before installing connectors or anchors.

Understanding the existing structure also helps in choosing the correct type of Masonry Connectors and Wall Ties. These components form the backbone of the tie-in process and contribute significantly to the wall's integrity. If you're joining at a corner or junction, positioning and measurements must be precise to avoid misalignment.

Choosing the Right Wall Ties and Connectors

Wall ties are essential in securing the connection between a new block wall and an existing structure. These components ensure loads are safely distributed while allowing for slight movement from thermal and structural stresses.

Selection depends on factors such as the material of both walls, exposure to weather, and construction type. Stainless steel is commonly used due to its corrosion resistance, while galvanised steel is effective for internal walls. Wall Starter Profiles offer an easy and reliable method for joining walls, especially for extensions or partial rebuilds. They maintain structural stability while simplifying installation.

When constructing in windy coastal areas or places with high structural demands, consider components like High Wind ties & timber connectors to ensure durability of the tie connection. Compatibility with the particular load conditions can avoid costly failures later. Correct spacing is critical—over-spacing reduces performance while under-spacing leads to rigidity and cracking.

Preparation and Surface Alignment

A properly prepared surface helps in anchoring the new wall solidly to the existing one. Surface irregularities can compromise the strength of both the connection and new wall.

Start by cleaning the attachment zone thoroughly. Remove debris, grease, loose mortar or paint that could affect bonding. If masonry anchors or ties are being drilled in, mark your layout beforehand to maintain alignment and spacing.

For uneven walls, packing shims or levelling mortar can correct irregular profiles. It's important that the surfaces come together in plane to avoid pressure points or gaps. A straight edge or plumb line will help maintain accurate level alignment across both surfaces. Consider using corner connectors or angle brackets when forming perpendicular junctions.

Utilise Masonry Connectors and Wall Ties that fit the depth and spacing of your block wall for best results. Proper surface prep extends their life and enhances bonding efficiency.

Fitting Wall Starter Profiles for Tie-In

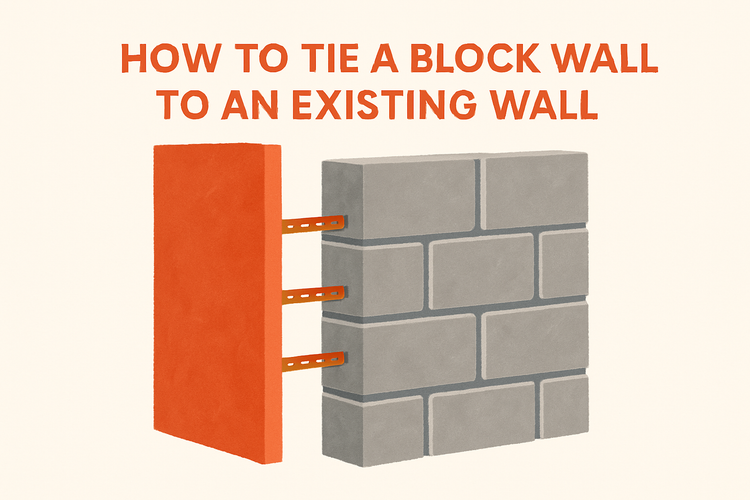

Wall Starter Profiles are commonly used for vertical joins in blockwork, such as where a new wall extends from the face of an existing wall. They simplify the construction process and reduce the need for site cutting ties.

These profiles typically consist of galvanised or stainless steel channels that are fixed to the existing wall. Metal ties provided with the pack are slotted at regular intervals into these channels as blockwork is laid. This provides a secure and flexible connection that accommodates thermal movement.

Make sure to attach the starter profile with suitable screws or wall plugs, depending on the wall type. Spacing should follow the manufacturer’s recommendations—normally every 225–300mm horizontally and vertically. Ensure profile alignment using a level both vertically and horizontally so that the new wall doesn't taper off or buckle.

These starter kits are especially helpful with lightweight block or timber-framed extensions, where rigid interlocking is necessary. For timber elements involved in the junction area, you may also explore Joist Hangers to secure bearing ends joining the blockwork.

Securing and Finishing the Tie-In

Once your wall is positioned and ties are fitted, the focus should be on securing every join point and providing final finishing for waterproofing and appearance.

As blockwork progresses, carefully insert each tie into the mortar joints, then fully bed with fresh mortar to ensure strength. Avoid dry placement or bending ties, which can weaken their performance. Regularly check the level and vertical alignment using a laser or plumb bob to avoid cumulative misalignment as the wall rises.

For external walls, apply a flashband or mastic sealant over the joint area to prevent water ingress. Once mortar has set, inspect each connector to ensure it’s firm and unobstructed. Any gaps should be filled or corrected immediately to prevent structural compromise.

Where timber framing joins masonry, combine traditional ties with Timber Frame Connectors to bind structural elements. Final plastering or external rendering may be applied after mortar curing to complete the integration of the new structure.