Common Mistakes With Timber Frame Connectors

Improper Selection of Timber Frame Connectors

Choosing the wrong type of timber frame connector can lead to premature failure and structural issues. This is one of the most common yet avoidable mistakes during timber construction projects.

Each connector is designed for specific load capacities and wood configurations. For example, using Joist Hangers intended for interior floor joists in exterior or high-wind areas can severely compromise the integrity of the structure. Builders must evaluate the load-bearing needs and environmental impacts before selecting connectors to ensure safety and longevity.

Additionally, the compatibility of materials must be taken into account to avoid corrosion or loosening over time. Pressure-treated timber, for instance, requires corrosion-resistant connectors to withstand chemical interactions. When designers and contractors overlook such nuances, they risk expensive repairs and compromised safety down the line.

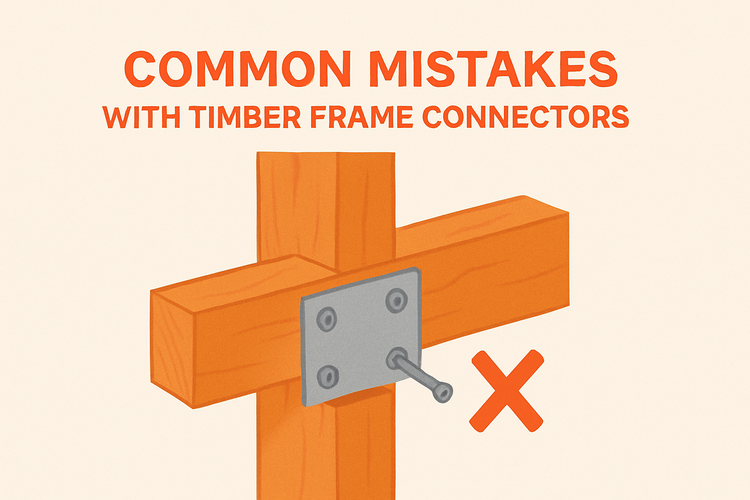

Incorrect Installation Practices

Even the best connectors can fail if not installed properly. Installation mistakes are often due to rushed work, lack of training, or ignoring manufacturer guidelines.

Proper alignment and secure fastening are crucial. Connectors must be flush with timber surfaces and installed with the recommended screws or nails. Using incorrect fasteners or omitting some entirely can result in weakening of the structure. Builders should consult product specifications, like those for Timber Frame Connectors, to ensure installation adheres to best practices.

Needless alterations like bending brackets or trimming parts to "make them fit" are common but detrimental. Doing so not only diminishes structural performance but often voids product warranties. If modifications are needed, alternative approved connectors should be used instead of attempting incompatible adjustments.

Detailed inspection after installation can eliminate headaches down the line. Special attention should also be paid to any fastening in concealed or hard-to-reach areas, where improper securing is more likely to occur without careful oversight.

Neglecting Environmental Conditions

Environmental factors such as humidity, wind load, and exposure to moisture are often underestimated when incorporating timber connectors.

Connectors exposed to outdoor elements need to be weather-resistant and rated for external use. For example, high-moisture environments demand the use of galvanized or stainless-steel options. Similarly, in regions experiencing strong winds, specialized products like High Wind Ties & Timber Connectors are critical to maintaining structural stability.

Ignoring such factors leads to corrosion, wood splitting, connector fatigue, and eventual failure. Timber structures exposed to seasonal changes undergo frequent expansion and contraction. Therefore, using standard connectors without accounting for movement can lead to loosened fittings over time.

This is particularly important for elevated decks, open frame buildings, or coastal homes, where environmental stress plays a constant role. Climate-responsive design and connector selection helps in preserving the integrity of the frame in high-risk scenarios.

Inadequate Load Path Consideration

Focusing solely on individual connectors without regard for the overall load path is a mistake seen in many timber frame assemblies.

Every component in a timber structure must properly transmit loads from point to point, down to the foundation. Failing to establish a continuous load path can result in overstressed connectors and uneven weight distribution. This is especially pertinent when integrating supporting elements such as Post Bases that serve as crucial transition points between posts and footings.

A common oversight is omitting or misplacing restraint or bracing elements that should accompany connectors. Without proper lateral and diagonal support, the connectors take on forces they weren't designed to handle. Structural engineers must ensure that every joint complements the overall force transfer strategy.

Evaluating the entire timber frame as a cohesive system rather than a collection of individual joints is essential. Attention to point loads, shear force directions, and moment resistance will dictate which connectors are appropriate and where reinforcement may be necessary.

Poor Maintenance and Inspection Over Time

Even after installation, timber frame connectors require regular inspection and maintenance to remain effective.

Timber naturally expands and contracts with seasonal changes, placing ongoing strain on connectors. Over time, fasteners may loosen, wood may begin to crack, and connectors may show signs of corrosion or fatigue. Catching these issues early is key to avoiding critical failures involving structural damage or complete connector detachment.

Routine checks—particularly in vulnerable areas like roof junctions, flooring frameworks, or exterior supports—help identify weak points. Areas reinforced with products like Joist Hangers or Post Bases should be visually inspected for rust, warping, or unauthorized modifications.

Preventative maintenance, including re-fastening displaced screws and cleaning debris from around exposed connections, prolongs the life of both the wood and its supports. Implementing a scheduled maintenance program for timber frame structures contributes directly to safety and cost-efficiency in the long term.